| 일 | 월 | 화 | 수 | 목 | 금 | 토 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| 22 | 23 | 24 | 25 | 26 | 27 | 28 |

- ni-paste

- BaTiO3

- Automotive

- oxygen vacancy

- Murata

- core-shell

- paste

- ASSB

- coating

- hydrothermal

- NI-MLCC

- Barium titanate

- CSZT

- nano powder

- CERAMIC

- Powder

- halt

- Sintering

- nickel

- X7T

- bme

- dispersion

- C0G

- microstructure

- Zirconia

- X8R

- mlcc

- ZrO2

- reliability

- EV

- Today

- Total

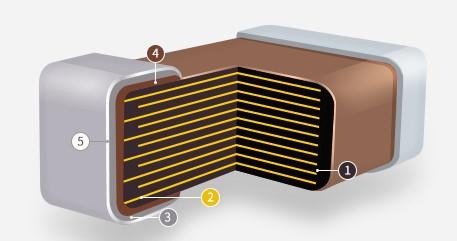

MLCC Material & Process

Liquid-phase preparation of BaTiO3nanoparticles 본문

- IET Nanodielectrics 3(25), DOI: 10.1049/iet-nde.2020.0021

Abstract:

Barium titanate (BaTiO3, BT) is widely used in the manufacture of electronic components such as multilayer ceramic capacitors, supercapacitors, thermistors, ferroelectric devices and piezoelectric devices due to its excellent dielectric, ferroelectric, piezoelectric and insulating properties. The performance of BT-based components is highly dependent on the quality of the BT nanoparticles. Large particle size and uneven distribution are the disadvantages of the BT nanoparticles synthesised by the traditional solid-phase reaction, however, the liquid-phase method can overcome these shortcomings, which has the characteristics of high purity and uniform composition with small particle size, and therefore is the main method for the preparation of BT nanoparticles. This review described various liquid-phase preparation methods of BT nanoparticles and compared the advantages and disadvantages of these methods, thereafter the optimised process parameters that affected the BT crystalline quality were summarised so as to obtain BT nanoparticles with a high crystalline quality, small particle size and even distribution

'Material' 카테고리의 다른 글

| 스크린 인쇄 등, 많은 인쇄 방식에 대응하는 페이스트용 폴리비닐아세탈수지, 에스렉®SV (0) | 2023.04.01 |

|---|---|

| 전자재료향 고비점용제 (0) | 2023.04.01 |

| 히로시마대에서 납계재료 대체가능한 강유전성과 압전성에 우수한 세라믹제료개발 (1) | 2023.03.19 |

| 나고야대에서 두께1.8nm의 강유전체 나노시트, 저온에서 합성가능 (1) | 2023.03.19 |

| Exceptional reliability of MLCCs enabled by defect-engineered BaTiO3 (0) | 2023.03.18 |